orals 5th Asia-Pacific NMR Symposium 2013

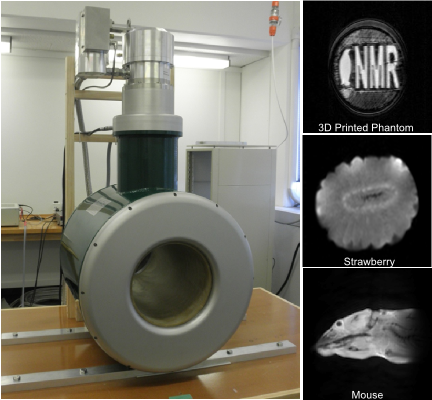

Construction of a 1.5T Cryogen-Free Animal Imaging System (#40)

Modern cryogen-free magnet design combined with miniaturization of the console electronics can provide easier access to MRI capabilities for a wide range of users. Making sophisticated MRI facilities no longer the preserve of pharmaceutical companies, leading research hospitals, and major academic or industrial labs, but makes it accessible to most biomedical researchers, smaller companies, colleges and developing countries that lack cryogen handling facilities. In our laboratory we have put together a 1.5T cryogen-free MRI system suitable for small animal imaging applications.

The MR system is built around a 1.5T cryogen-free magnet with 260mm wide bore and relies on a two stage pulse tube cold head. Magnet is wound using low temperature superconducting wire NbTi, entire assembly is then embedded in epoxy and cooled down to 4.2 K. A water-cooled helium compressor F50H (Sumitomo Heavy Industries Ltd, Tokyo, Japan) is used to power and operate the pulse tube cold head. During a power failure or a quench the energy in the coils is partially extracted using high power diodes in the magnet power supply, the rest is thermally and safely dissipated internally in the magnet.

A compact digital electronics console based on Kea 2 (Magritek Ltd, Wellington NZ) was used to drive peripheral system electronics. The console is based around a digital transceiver board capable of operation from 0-400MHz.

Cryogen free magnets are rapidly becoming viable for dedicated MRI systems1. Their main advantages are that they can easily be power cycled and stored for extended periods of time without needing cryogens to cool them down again.

Figure 1: 1.5 T Cryogen-Free MRI system and Acquired Images

- Lvovsky, Y. and Jarvis, P. Superconducting systems for MRI-present solutions and new trends. IEEE Transactions on Applied Superconductivity (15) 1317--1325 2005